Quality Inspection

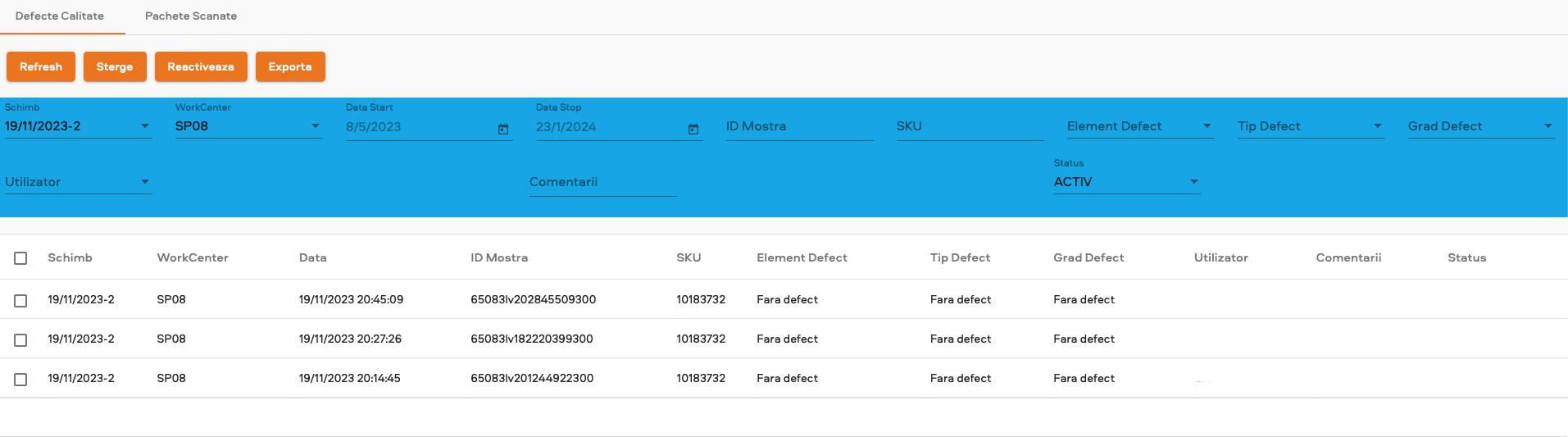

Defect Identification:

Pinpoint and categorise defects with precision using the app’s intuitive interface. Whether it’s a flaw in manufacturing, packaging, or assembly, Quality Inspection allows you to capture and classify defects seamlessly.

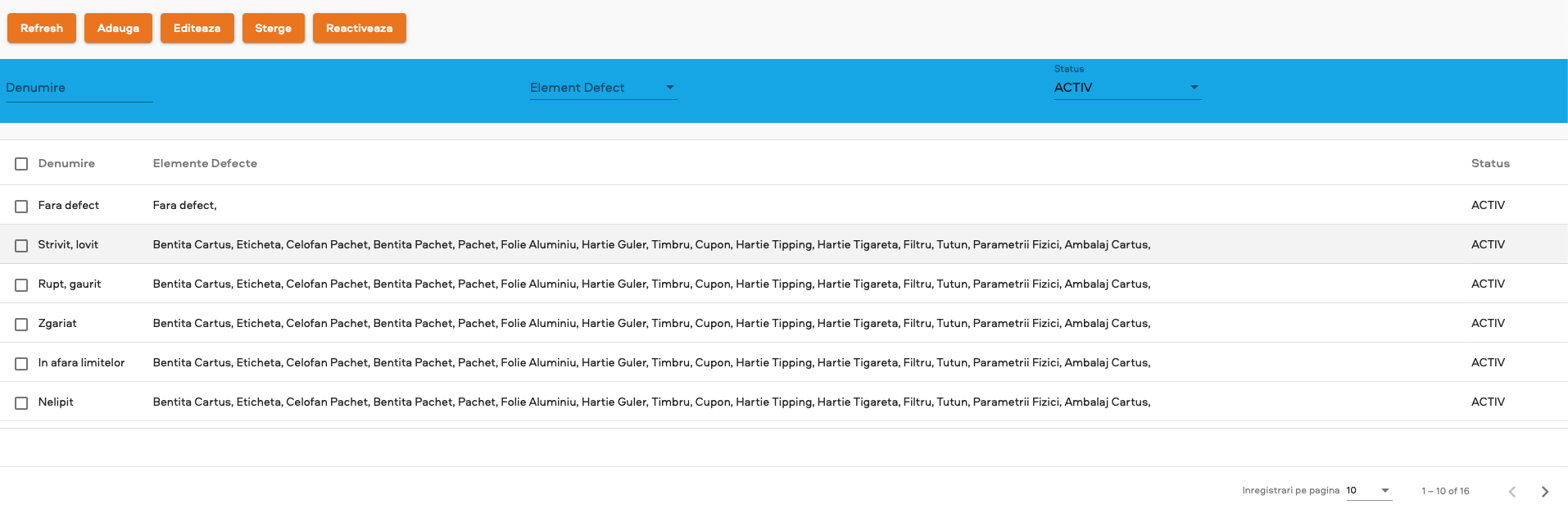

Customisable Defect Profiles:

Tailor the app to your unique production needs by defining specific defect profiles. From material imperfections to assembly errors, you have the flexibility to create and modify defect categories that align with your industry standards.

Product Association:

Associate identified defects with specific products effortlessly. By linking defects to individual products, you gain granular insights into the quality performance of each item in your production line.

Comprehensive Reporting:

Generate detailed reports on defect trends, product-specific issues, and overall quality performance. These comprehensive insights empower decision-makers to implement targeted improvements and optimisations.

Streamlined Communication:

Facilitate seamless communication between production teams and quality control personnel. Instant notifications and alerts ensure that everyone is informed of defects and can take immediate corrective actions.

Historical Data Analysis:

Leverage historical data to identify recurring issues and root causes. By analysing patterns, you can implement proactive measures to prevent similar defects in future production cycles.